Systems

By "System" we mean the frame, anchored to the wall support, which is necessary to support the whole cladding and/or the louvered opening.

As it comes to external environments, we have selected materials that can ensure all the needed requirements such as resistance to atmospheric agents and corrosion due to pollution.

Each of our systems guarantees free movement in the three axes so as not to create stress of any kind among the various elements.

The market offers a wide range of applications that tend to standardize the assembly of various claddings; however, modern architecture is constantly evolving and needs customized solutions each time.

Eureka Project is able to design and produce customized ad hoc systems as well as standard ones.

-

EUREKA .1

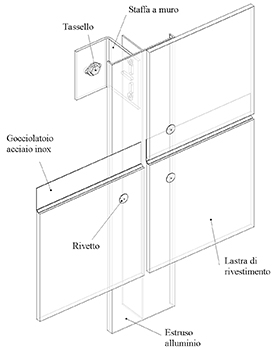

This ventilated façade system is cheap and functional.

It is composed of 6063-T6 aluminium alloy extrusion profiles vertically mounted with wall brackets and their anchors. The fastening - strictly visible - can be "camouflaged" (the heads of the rivets are painted in a similar colour to the cladding slab) or put in evidence (customized studs to give the effect of nails). This system is especially suitable for large slabs (Fiber cement and HPL laminate).

The possibility of inserting a closing profile in the horizontal groove and the special shape of the profile section make the system fully waterproof.

-

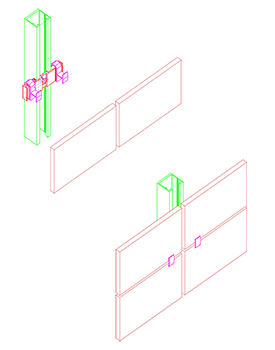

EUREKA .2

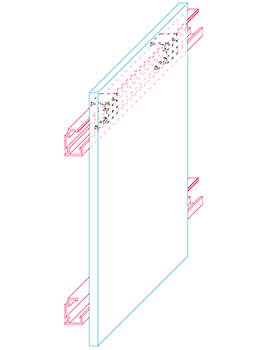

(Hidden fastening)

Some EN-6063-T6 aluminium alloy horizontal profiles are fixed to the primary (vertical profiles) to support the clips connecting the cladding slabs.

The Clip/Slab connection involves the use of undercut technology. Some threaded bushes are inserted on the back of the slab in order to be connected to the clips themselves.

It is particularly indicated when the fastening must be strictly invisible; it is mainly used on stone and porcelain stone claddings.

-

EUREKA .3

(Semi-visible fastening)

This system is normally used for stone or terracotta claddings; the first ones require milling (kerf), while the second ones are made by extruding clay.

This type of traditional connection is based on anchoring the structures by means of special brackets whose shape allows to support the slab from the bottom and prevent the overturning of the one below. In this case, some vertical elements are used according to the slab module; they are made up of C-shaped uprights so as to allow the insertion of threaded plates whose sliding allows the adjustment and then the locking of the aluminium plate holding brackets. The EN-6063-T6 aluminium alloy uprights have special loops for the connection to the masonry by means of anchors of the appropriate type.

-

EUREKA .4

(Visible fastening, visible clips)

This system is composed of C-shaped uprights so as to allow the insertion of threaded plates whose sliding allows the adjustment and then the locking of the carrier plates on which the plate holding brackets are inserted All the uprights have special loops allowing the connection of the structure to the masonry by means of suitable anchors.

The anchoring of the cladding to the structure is performed by means of carrier brackets on which the slab holding brackets (Clips) are inserted on the sides. These brackets are "stopped" inwards by a relief on the front of the carrier bracket and outwards by stainless steel flat springs. The removal of the involved cladding is simple: press the locking spring by means of a special screwdriver and with a normal screwdriver make the "clip" slide until it is released from the carrier bracket; repeat the operation on the opposite side of the cladding slab. At this point, if you pull outwards you release two slabs.

In order to align the vertical joints and to avoid the instability due to the play between the bracket and the plate, there are some springs acting as a clamp and spacer. This system is normally used for porcelain stone slabs of various sizes.

-

EUREKA .5

(Semi-visible fastening)

This system involves the use of slabs with kerf (longitudinal milling on both edges). There are some C-shaped uprights so as to allow the insertion of threaded plates whose sliding allows the adjustment and then the locking of the carrier plates on which the plate holding brackets are inserted. All the uprights have special loops allowing the connection of the structure to the masonry by means of suitable anchors.

The anchoring of the cladding to the structure is performed by means of carrier brackets matching the Clips (slab holding brackets) which are inserted in the kerf. These brackets are "stopped" inwards by a relief on the front of the carrier bracket and outwards by stainless steel flat springs. The removal of the involved cladding is simple: press the locking spring by means of a special screwdriver and with a normal screwdriver make the "clip" slide until it is released from the carrier bracket; repeat the operation on the opposite side of the cladding slab. At this point, if you pull outwards you release two slabs.

In order to align the vertical joints and to avoid the instability due to the play between the bracket and the plate, there are some springs acting as a clamp and spacer.

-

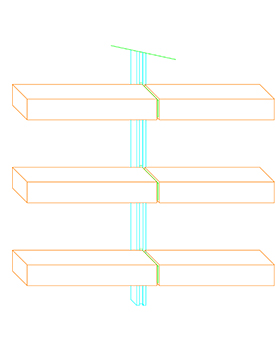

EUREKA .6 Louvered opening

This system is composed of tubular uprights so as to allow the insertion of threaded plates whose sliding allows the adjustment and then the locking of all couplings.

The fastening to the walls of the building is made by means of carrier brackets blocked to the existing masonry, with mechanical and/or chemical anchors of the appropriate type (fixed points) and retaining brackets (movable points) connected to the masonry in the same way. The connection between the carriers and the horizontal structure (louvered opening) is performed by means of flag brackets whose shape allows to create an "invisible" and inspectable fastening system. In particular, the louvered openings are suspended by means of an aluminium extrusion tubular structure connected to the flag brackets by screws.

The flags disappear into the 6-mm groove of the louvered opening. Each row can be individually removed so as to allow the maintenance and/or replacement of the elements. This system is normally used for tubular systems in terracotta, porcelain stone, composite wood, etc.

-

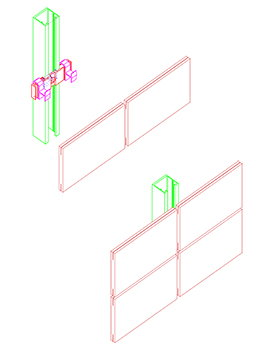

EUREKA .7

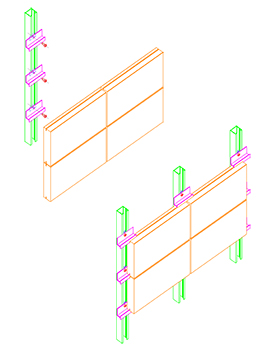

(Multi-modular system)

This system has resulted from the need to create a completely customizable façade or cladding: by changing the accessories, it is possible to assemble elements of different types and/or sizes on the same upright.

Therefore, depending on the designer's request, we can create the accessory suitable for the purpose each time.

Here you can see the fast composition and result of a wall made with this system.

-

EUREKA .0

Custom-built systems for specific architectural or functional needs.

For any further request or information, please do not hesitate to contact us.